October 8, 2020

October 8, 2020

Historically, when we think about manufacturing facilities, we think about massive, vastly populated shops that churn out all of the industrial pieces, parts, and products that fill our everyday lives. Manufacturing plants were at the forefront of our economy offering countless jobs to any and all people looking to get into “the trades.” Things changed drastically when we started offshoring manufacturing work overseas in the 1960s, which steadily increased on through the 80s, and is still a much talked about topic today, some 40 years later. Reshoring manufacturing jobs is a hot, always trending topic, and for very good reason.

Benefits of reshoring industrial manufacturing work to our factories on U.S. soil include:

- Increased job opportunities for our fellow Americans

- Reduced cost for delivery of manufactured goods

- Vastly shorter lead times

- More environmentally friendly

- A higher safety and quality standard across the board

- Better, more meaningful customer service

- And, hey, U.S. manufacturers pay U.S. taxes, so…

Sure, we might be biased given that we’re a manufacturer here in these United States, but, doesn’t that all make good sense? We think so.

A lot of those massive buildings we mentioned above now sit barren, boarded up, and looking like they’re being preserved for a scene in an upcoming horror flick. There are certainly big operations still churning out manufacturing work, but, by-and-large a lot has changed in the industrial landscape and now more than ever there’s been a shift to “micro-manufacturing.”

What is micromanufacturing?

“Micromanufacturing is the manufacturing of products in small quantities using small manufacturing facilities.”

What this means is, not everyone is doing it. There’s a substantial contingency of manufacturing operations that don’t have the bandwidth, tools, or desire to create pieces and parts on a small scale. Their operation is set up to exclusively handle enterprise sized contracts.

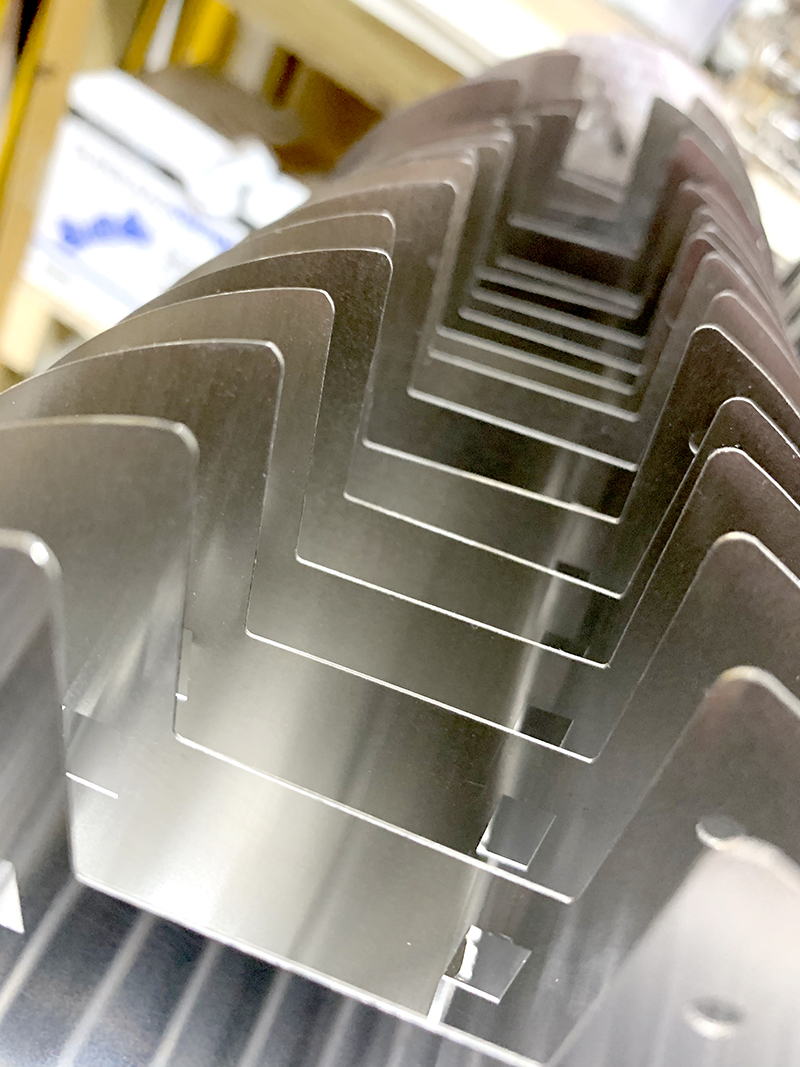

For some us, such as us here at MuShield, we can handle the large contracts, but also have the flexibility, knowledge, and resources to switch gears and offer our services for smaller jobs. Hello micro-manufacturing!

We’ve spoken at length in the past about our engineering team who can help you through any need you might have – in essence they can take your idea and convert it into a working blueprint, and further, a piece or part fully brought to fruition. An invaluable R&D resource as it were…

MuShield is an invaluable partner that you can look to when it comes to a need for helping you through a project when you need someone to simply produce a piece of the greater whole. This just happens to be an integral part of the micromanufacturing topic we’re diving into here. Micromanufacturing is not about very tiny parts, it’s more about, specialized focuses, chewing off small pieces of a manufacturing job, and/or producing small runs where a vast quantity is not needed.

What’s the benefit of micromanufacturing?

Well, we’d argue that benefit ought to read, “benefits,” but, the overarching point here is this:

While we can’t all afford every machine we might need to create every desirable component of manufacturing, we can work together to tap into each of our inherently unique resources and become a stronger, (re-shored!) manufacturing giant. Right? Right! Micromanufacturing for the collective win!